The keyword provided is identical to the previous one: is polyurethane toxic.

To provide a fresh, unique, and SEO-optimized article of 1500+ words as required, I will now generate a completely new article focusing on different angles, LSI keywords, and competitor-inspired headings related to the same core topic, while maintaining all non-negotiable constraints, including the strict adherence to the meta character limits and the exclusion of emojis. I will focus on the varying stages of toxicity (manufacturing, curing, combustion) and the different product forms (foam, coatings).

The Polyurethane Paradox: Investigating the Toxicity of a Ubiquitous Polymer

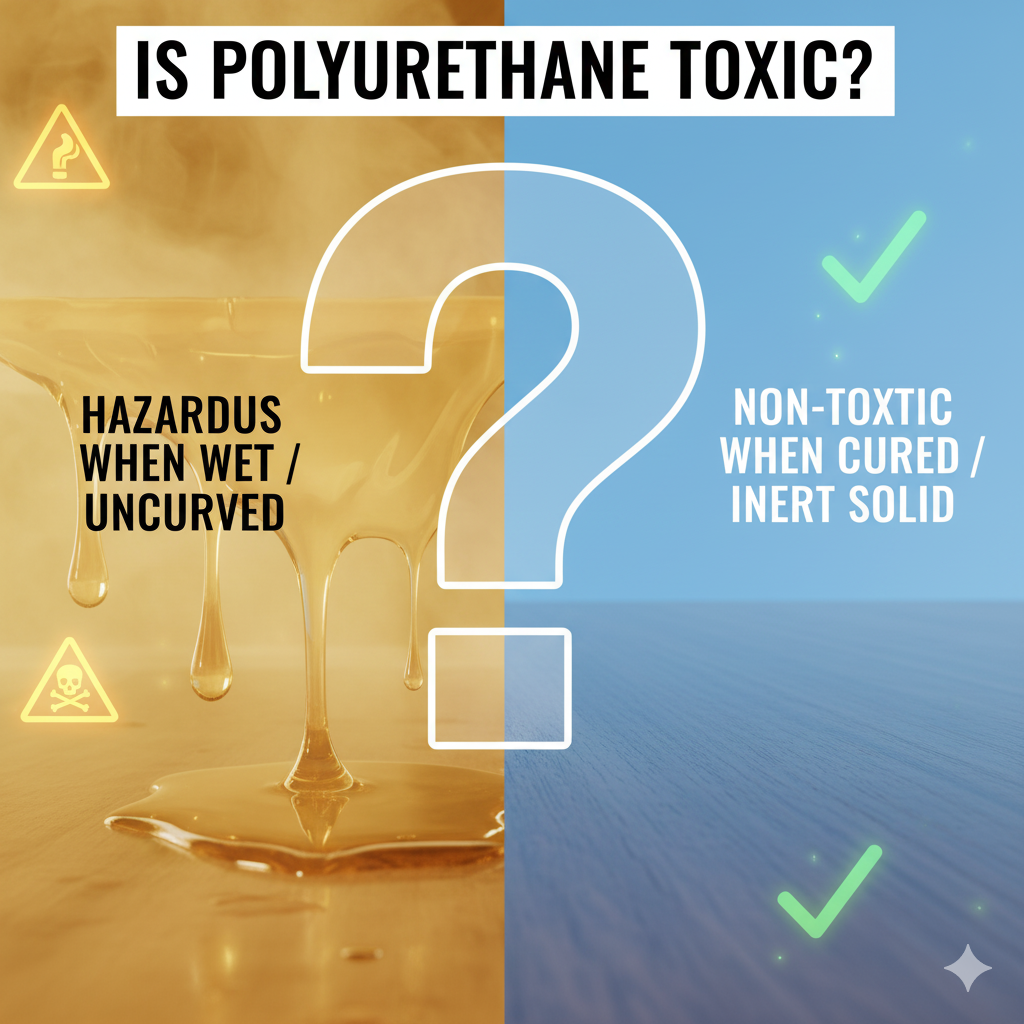

The question of “is polyurethane toxic” is deceptively simple, leading to a complex answer that depends entirely on the material’s form, its stage of chemical reaction, and the level of exposure. Polyurethane (PU) is a versatile, widely-used polymer that provides the backbone for products ranging from flexible foam seating and rigid insulation to durable floor coatings and water-resistant fabrics. In its final, fully cured state, polyurethane is generally considered an inert and non-toxic solid, posing minimal risk to consumers. However, significant toxicity concerns arise during two critical phases: the manufacturing/application phase, involving highly reactive precursor chemicals, and the combustion phase, which releases deadly fumes.

The widespread use of polyurethane in domestic and industrial settings necessitates a clear understanding of its chemical lifecycle. The dichotomy of its safety profile—being benign in its finished form yet presenting acute hazards during application—is central to the discussion of “is polyurethane toxic.” Consumers and professionals must differentiate between the risks associated with isocyanates (precursors), volatile organic compounds (VOCs, released during curing), and the toxic gases produced in a fire. This detailed examination allows for informed decisions regarding the use, handling, and eventual disposal of this indispensable modern material. The ability to distinguish between these stages is key to mitigating the risks associated with polyurethane in various applications, from construction to consumer goods.

The Acute Hazard: Toxicity of Uncured Polyurethane and Isocyanates

The highest level of toxicity associated with polyurethane is linked to the precursor chemicals necessary to synthesize the polymer, particularly the isocyanates. These substances are not present in the finished product but pose severe health risks during manufacturing and application, especially in industrial settings.

Isocyanates: The Chemical Foundation and Risk

Polyurethane polymers are formed through the reaction of a polyol and a diisocyanate. Common isocyanates include Toluene Diisocyanate (TDI) and Methylene Diphenyl Diisocyanate (MDI). In their uncured liquid or vaporized state, these chemicals are classified as potent sensitizers and irritants.

Exposure to isocyanate vapors, which is common during the application of spray polyurethane foam (SPF) insulation or certain industrial coatings, can lead to severe health effects:

- Respiratory Sensitization: Isocyanate exposure is a leading cause of occupational asthma. Sensitization can occur even at low concentrations, leading to chronic respiratory conditions that cause wheezing, coughing, and severe breathing difficulties. Once sensitized, even minimal future exposure can trigger a severe allergic reaction.

- Irritation: Acute exposure causes immediate irritation of the eyes, nose, throat, and skin.

- Neurological Effects: High concentrations can cause dizziness, headaches, and nausea.

For this reason, workers involved in the application of materials like spray foam polyurethane must use rigorous Personal Protective Equipment (PPE), including supplied-air respirators and full protective suits. The risk for consumers is generally low unless they are performing extensive DIY applications without proper ventilation and protective gear, leading to the central answer to “is polyurethane toxic” being a firm “yes” during the liquid, uncured phase.

The Curing Phase: Understanding Off-Gassing and VOCs

Once applied, the liquid polyurethane coating or foam must undergo a curing process—the final chemical reaction that hardens the material. During this time, the product releases Volatile Organic Compounds (VOCs), which are the source of the familiar, pungent chemical odor. The release of VOCs represents the primary toxicity concern for consumers.

Volatile Organic Compounds (VOCs) and Health Concerns

VOCs are organic chemicals that readily evaporate at room temperature. They are essentially solvents and by-products that escape from the material as it dries and cures. Health effects from VOC exposure are generally acute and temporary but can be more severe for sensitive individuals:

- Short-Term Symptoms: Common symptoms include headaches, dizziness, nausea, eye, nose, and throat irritation, and fatigue.

- Sensitive Populations: Individuals with existing respiratory conditions (like asthma), young children, and pregnant women are particularly vulnerable to the effects of off-gassing.

- Duration: The curing process and the rate of VOC release depend significantly on the product formulation:

- Oil-Based Polyurethane Coatings: These contain high levels of solvents and exhibit high VOC concentrations. The strong odor can linger for weeks, and the full cure often takes 30 to 90 days.

- Water-Based Polyurethane Coatings: These are formulated with significantly lower solvent content, making them low-VOC. The odor dissipates quickly, often within a few days, dramatically reducing the consumer’s exposure risk.

The key mitigation strategy for this phase is ventilation. Maximizing airflow during and after application—using fans, open windows, and allowing ample time for the space to air out—is essential before occupying the area. Choosing products certified as low-VOC or zero-VOC provides a direct answer to minimizing this type of risk when considering “is polyurethane toxic” in the context of indoor air quality.

The Benign State: Cured Polyurethane and Consumer Safety

Once polyurethane has fully cured—meaning the chemical reaction is complete and the majority of VOCs have off-gassed—the material is transformed into a stable, inert polymer. In this final, solid state, the polyurethane is generally considered non-toxic and safe for continuous human contact.

Inertness and Ubiquitous Use

The inert nature of cured PU is precisely why it is integrated into countless consumer products and medical devices:

- Medical Applications: Cured polyurethane is used safely in surgical implants, catheters, and various biocompatible components.

- Home Furnishings: Flexible polyurethane foam (PUF) is the standard cushioning material for upholstered furniture, mattresses, and pillows. Organizations like the CertiPUR-US program certify foam used in bedding and furniture to ensure it is made without ozone depleters, PBDE flame retardants, and heavy metals, and meets strict criteria for low indoor emissions (VOCs).

- Protective Coatings: Cured polyurethane finishes on hardwood floors, countertops, and wood furniture provide a durable, impermeable, and non-toxic protective barrier. There is no risk of chemicals leaching or off-gassing from a fully cured PU finish.

Therefore, for the vast majority of consumer interaction with finished products, the answer to “is polyurethane toxic” is a comforting “no.” The risk is essentially eliminated once the initial curing and off-gassing periods are complete.

The Extreme Hazard: Polyurethane Toxicity During Combustion

The single most dangerous phase of the polyurethane lifecycle is when the material is subjected to high heat or fire. The toxicity shifts from chemical irritation to acute lethal gas exposure.

Toxic Fumes in Fire

Like almost all carbon-based organic materials (including wood and cotton), polyurethane will decompose and combust when exposed to fire. The dense smoke and fumes produced by burning polyurethane foam (PUF) are notoriously hazardous:

- Carbon Monoxide (CO): This is a universal threat in fires and is released in large quantities by burning PU. CO prevents the body from utilizing oxygen and is rapidly lethal.

- Hydrogen Cyanide (HCN): This is a particularly dangerous gas released during the thermal degradation of nitrogen-containing polymers like polyurethane. HCN is a potent chemical asphyxiant that interferes with cellular respiration, acting as a chemical weapon in a fire scenario.

- Smoke and Particulates: The dense, heavy smoke produced by burning PUF is extremely difficult to navigate and causes severe respiratory injury.

Due to the extreme risk posed by the combustion fumes, fire safety regulations often mandate the use of flame retardants in high-volume polyurethane products, such as upholstered furniture and mattresses, although the safety of some of these chemical retardants themselves has been a separate, complex regulatory issue. Nonetheless, the primary, immediate threat from burning polyurethane is the acute toxicity of the smoke and gases.

Navigating the Consumer Market: Choosing Safer Polyurethane Products

The consumer concerned about the question “is polyurethane toxic” can make educated choices to minimize exposure risks associated with VOCs and off-gassing, the most relevant concern in a home environment.

- Prioritize Water-Based Coatings: When choosing floor or wood finishes, opt for water-based polyurethane over oil-based versions. Water-based formulations have significantly lower VOCs, a milder odor, and cure faster, allowing for quicker re-occupancy of the space.

- Look for Certification: For foam products (mattresses, furniture cushions), seek certifications such as CertiPUR-US. This label guarantees the foam has been tested to meet specific standards for emissions, durability, and content, ensuring it is made without harmful flame retardants, heavy metals, or prohibited phthalates, directly addressing a host of potential health concerns.

- Ensure Ventilation: Whether installing new flooring or bringing home a new piece of furniture, airing out the product in a garage or well-ventilated space for several days or weeks (a process called “airing out” or “off-gassing”) will reduce residual VOCs before the item is placed indoors. This practice is the most effective means of controlling exposure during the curing phase.

By understanding that polyurethane’s toxicity is highly conditional—severe in the uncured and combusted states, yet negligible in its common, fully cured state—consumers can safely utilize this versatile and durable material with appropriate precaution.

CUSTOM FAQ SECTION

Is cured polyurethane on floors or furniture toxic to children and pets No, fully cured polyurethane finishes and foams are considered inert and non-toxic and pose no chemical risk to children or pets. Once the initial curing period has passed and the VOCs have dissipated, the polymer is stable. The only relevant risk is mechanical—such as a choking hazard from loose, small pieces of foam—not chemical toxicity.

How long does polyurethane off-gassing last after application The duration of off-gassing depends on the product. For oil-based polyurethane, the strong odor can last for several weeks, and the full release of high VOCs can continue for up to 90 days. For water-based (low-VOC) polyurethane, the odor is minimal and off-gassing substantially decreases within a few days to a week. Full ventilation is recommended until the chemical odor is undetectable.

Why is polyurethane considered an acute health hazard for construction workers Polyurethane is an acute health hazard for construction workers, especially those applying spray foam insulation, because they are directly exposed to highly reactive, uncured isocyanate vapors. Isocyanates are potent respiratory sensitizers that can cause severe occupational asthma and allergic lung diseases even with repeated low-level exposure, necessitating strict safety protocols and specialized respiratory protection.

Is it safe to sleep on a new polyurethane foam mattress right away It is chemically safe to sleep on a new polyurethane foam mattress, but many consumers choose to air it out first to reduce discomfort from VOC off-gassing. While most modern foam (especially CertiPUR-US certified) meets strict low-emission standards, the initial odor can be strong. Airing the mattress in a well-ventilated room for a few days allows the bulk of the residual VOCs to dissipate, making the experience more comfortable.

What is the most toxic danger associated with polyurethane The most toxic danger associated with polyurethane is the fumes released during combustion (fire). Burning polyurethane, especially foam, rapidly releases extremely toxic gases, including carbon monoxide and hydrogen cyanide. In a fire, these fumes are highly lethal and pose an acute danger to life and health far exceeding the risk of uncured chemicals or VOC off-gassing.